Diagram how bird wings work. Source: http://www.youtube.com/watch?v=3So7OMwNgy8

Even though so simple, and many drawings I had seen so far should have explained the same concept, only now it made sense to me. I think possibly because it was the first clear top view showing the muscle and bone structure at once, but finally now I could understand how the wing should fold. I also see now that it probably had confused me from drawing my scale drawings from a front view, which would actually be the bottom of the bird and thinking that from there the wings should fold backwards, while actually it would look like they were folding sideways/up and down from the front, which in flight position would look like back and forwards. Oh well... what is back, side and front for a creature flying freely through the air? Clearly a lesson to define that better for myself next time... Anyway, this time I don't think I will have to re-design the entire wing, but can get away with just changing the direction of the hinge joint be re-soldering, and also adding an extra ball joint at the shoulder joint so it will be able to move more freely in all directions, which is quite important for this joint and I think was too limited with just one single ball joint...

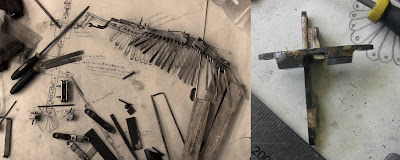

I drew out the new adjustments in a new scale drawing, also incorporating other changes I've made along the way, and some new thoughts about the tail, where I'm now applying a similar mechanism as to the wing feathers. I made some pictures of the scale drawings, hopefully can make a better scan of it soon, but it hopefully makes some things clear for now.

I drew out the new adjustments in a new scale drawing, also incorporating other changes I've made along the way, and some new thoughts about the tail, where I'm now applying a similar mechanism as to the wing feathers. I made some pictures of the scale drawings, hopefully can make a better scan of it soon, but it hopefully makes some things clear for now.

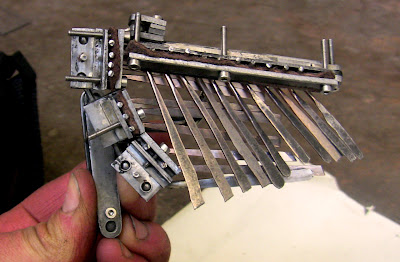

Close up of the new wing design.

Full bird scale drawing - (not ultimate quality image).

The other elements except the adapted wing design which I incorporated in this new scale drawing are the new design for the leg attachment, as how I sketched it roughly some time ago. Also I skipped the k&s at the feet part of the legs. I thought I needed them to be able to separate the feet when casting them separate from the rest of the body, but now realized that I can still easily detach them, as it is just a matter of unscrewing the hinge joint... I changed the fanning mechanism for the tail as mentioned above and changed the direction of the joints for the middle body parts, which I had already figured out before and applied on the armature, but is still shown different in the previous drawing. I also thought again about the positioning and direction of the tail joints and decided that to have the most options with quick twists and bends I should have one joint facing sideways and one the other way around, so I can have both free movement up and down as well as sideways. I also worked out the facial mechanism on here this time, which I had only done roughly from one side before, and the different viewpoints only in a rough sketch. I changed some things from this sketch also, after studying the bird's skull anatomy more. I hope this design will make sense when I start building it... hopefully it will require less versions then the wing... So far it's designed to have an opening beak, also some up and down movement of the upper jaw, movable eyelids, an attachment point for tongue (will be wire in k&s) and then the joint to the neck. Or so is the plan right now at least...